Nothing is ever easy…

The big problem with all these types of projects is that nothing is available off the shelf.

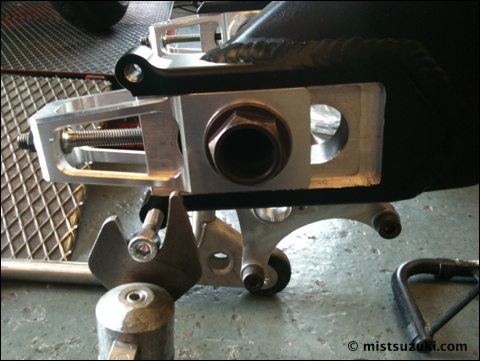

I managed to buy the suspension linkage, then I had to get some hardened spacers, then some of those hardened spacers had to be machined. Then I had to find the right length and type of bolts to give enough clearance.

Having the wiring harness made is relatively painless, albeit expensive, but every sensor has to be in position first, so a dozen or so one off brackets have to be designed and made.

When we ran in the BSB Evo class in 2010 we had a wiring harness made but most of the sensors stayed were they were on the stock bike. On this bike everything will move, the battery will be in a new position, the tip over sensor is being replaced by an HRC item, the regulator/rectifier is an aftermarket item, etc.

The bespoke dash bracket we used last year was quite simple, one major connector for the dash and one to allow us to hook up the laptop to connect to the electronics. We found we still had plenty of wires for various sensors, etc. getting in the way. This time the dash bracket will have connectors for the front potentiometer, front brake pressure sensor, etc. and then plenty of internal wiring to give us another big connector to bring everything together and connect it to the main harness.

We are hoping to use a fuel tank that will centralise the weight distribution of the bike. This then needs a different rear subframe, in fact it’s so small you could hardly even call it a subframe. This positions the standard fuel pump a lot further back so we need a new fuel line which, of course, requires that we modify both the end of the pump and the fuel rail that sits on the throttle bodies.

Everything takes time and money.